In the Spring of the year, we scout about for dead or near dead trees, fell them, and cut the logs into 16" to 18" pieces to fit into the stove fire box. Many types of trees are available, but we have been cutting maple, aspen, ash and birch trees. We prefer the hardwood such as oak, but oak is not available. The need for a wood shed was obvious.

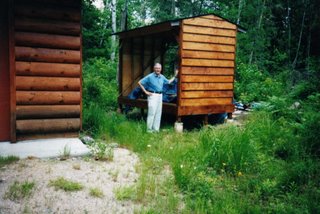

The 6' wide by 12' long wood shed is located about 8' from the garage. It is placed atop a sloping ledge rock: the same area we originally planned to locate the cabin. It is not the best place, but a good location and convenient.

The 6' wide by 12' long wood shed is located about 8' from the garage. It is placed atop a sloping ledge rock: the same area we originally planned to locate the cabin. It is not the best place, but a good location and convenient.Building atop the sloping ledge rock was a challenge. A level floor was desirable so, we cut 4 - 10" round forms (sonotubes) to fit the slope of the ledge rock. Jim, a friend who can solve the most difficult of problems, accepted the task of drilling four holes into the ledge rock for the vertical reinforcing rods, 1/2" in diameter. Jim proceeded with an electric drill and 1/2" diameter carbide tipped drill bits. The rock was very, very hard and the drilling very, very difficult. After many hours of drilling and wishing we had diamond tipped drill bits, we accepted about 1-1/2" deep holes. While Jim was drilling the holes, I busied myself by gathering the bags of sack-crete, the wheel barrow, shovel and water for mixing the concrete. We placed the reinforced rods into the holes and poured concrete into the forms (sonotubes). The tops of the poured concrete piers were now level and ready for the wood posts and other wood framing .

After waiting several days for the concrete to gain strength, we placed 4" x 4" treated wood posts atop the concrete piers and placed wood rafters to form the sloping roof. My daughter and I placed the plywood sheathing over the rafters and applied 30 pounds building paper. Next we nailed asphalt shingles (GAF, Timberline) over the building paper, forming a roof over the wood shed. The same shingles were used as were used on the cabin and garage. We also applied the same stain.

After waiting several days for the concrete to gain strength, we placed 4" x 4" treated wood posts atop the concrete piers and placed wood rafters to form the sloping roof. My daughter and I placed the plywood sheathing over the rafters and applied 30 pounds building paper. Next we nailed asphalt shingles (GAF, Timberline) over the building paper, forming a roof over the wood shed. The same shingles were used as were used on the cabin and garage. We also applied the same stain.The capacity of the wood shed is about three regular cords of wood, but the usual load is less than 2 cords. It is most enjoyable to sit on the nearby couch and watch the wood burning in the fire box of the Avalon Stove. The heat is a radiant type of heat and feels more comfortable than convection heat. Grab a cup of coffee, a good book and savor the warmth of the stove.